Você deseja escolher equipamentos de ligação por indução que correspondam às suas necessidades. Antes de começar, você deve conhecer seu material, seu processo e seus objetivos de produção. Muitos fabricantes têm problemas como:

Manter a temperatura certa para ligações fortes e seguras

Escolher materiais que funcionam bem com indução

Lidar com equipamentos e etapas difíceis

A Canroon ajuda você a aprender sobre essas coisas e oferece conselhos especializados para ajudá-lo a decidir.

Principais Conclusões

Descubra o que você precisa unir. Pense nos materiais que você usa. Analise seu processo e seus objetivos de produção. Saber essas coisas ajuda você a escolher oequipamento certo.

Escolha as configurações de potência e frequência que se adequam aos seus materiais. Use alta potência para peças grossas. Use baixa potência para peças finas.

Escolha um design de bobina que corresponda ao formato da sua peça. A bobina certa fornece calor uniforme. Isso torna a ligação mais forte.

Pense no tamanho e na facilidade de mover o equipamento. Certifique-se de que ele caiba no seu espaço de trabalho. Deve ser fácil de usar. Isso ajuda você a trabalhar melhor.

Escolha um fornecedor em quem você pode confiar. Eles devem oferecer bom suporte e equipamentos de qualidade. Um bom serviço ajuda você a evitar erros e interrupções no trabalho.

Defina Suas Necessidades de Aplicação

Antes de escolherequipamentos de ligação por indução, você deve saber o que precisa. Isso ajuda você a encontrar equipamentos que se adequam aos seus materiais, espaço e objetivos. Você tomará decisões mais inteligentes se começar com fatos claros.

Requisitos de Material e Processo

Você deve saber quais materiais deseja unir. A ligação por indução funciona com muitos materiais. As pessoas frequentemente a usam para metais, plásticos, vidro e borracha. A tabela abaixo mostra alguns pares comuns:

Diferentes materiais aquecem de maneiras próprias. Metais como o aço esquentam rápido porque têm alta resistividade. Cobre e alumínio demoram mais para aquecer porque têm baixa resistividade. Materiais magnéticos esquentam mais facilmente, mas os não magnéticos precisam de mais potência. Se o seu material é grosso, leva mais tempo para aquecer. Se o seu material não conduz, você pode precisar de um suscetor condutivo para ajudar no aquecimento.

Dica: Anote todos os materiais que deseja unir. Verifique se eles conduzem, quão grossos são e se são magnéticos. Isso ajudará você a escolher a bobina e a potência certas para o seu equipamento de ligação por indução.

Escala de Produção e Espaço de Trabalho

Pense em quantas peças você precisa unir e onde usará o equipamento. Se você produz muitas peças, precisa de equipamentos que funcionem rápido e possam lidar com grandes trabalhos. Se você produz lotes pequenos ou peças personalizadas, pode querer um sistema de indução portátil que caiba no seu espaço.

Grandes fábricas usam sistemas fixos de aquecimento por indução para velocidade e trabalho constante.

Pequenas oficinas podem preferir equipamentos pequenos ou móveis para mais opções.

O tamanho do seu espaço de trabalho importa. Certifique-se de que seu equipamento caiba e deixe espaço para segurança.

Você também deve pensar na facilidade de uso do equipamento. Controles simples e telas claras ajudam você a ensinar os trabalhadores e evitar erros.

Resultados de Ligação Desejados

Você precisa definir metas claras para seus resultados de ligação. Uma boa ligação significa juntas fortes, limpas e duráveis. Você pode verificar seus resultados de diferentes maneiras:

Os resultados da ligação afetam como seu produto funciona ao longo do tempo. Por exemplo, alguns adesivos absorvem mais água que outros. O Sikadur absorve cerca de 60.77% de sua massa após um longo tempo, mas o Loctite absorve cerca de 182.59%. Esses números mostram por que você precisa combinar seu método de ligação com seu ambiente. Envelhecimento e estresse podem mudar a força da ligação. Você deve testar suas ligações e escolher equipamentos de ligação por indução que ajudem você a alcançar seus objetivos de qualidade.

Nota: Necessidades claras ajudam você a escolher o sistema de aquecimento por indução, o design da bobina e as configurações de potência certas. Isso torna todas as outras escolhas mais fáceis.

Principais Características dos Equipamentos de Ligação por Indução

Seleção de Potência e Frequência

Você tem que escolher a potência e a frequência certas para o seuequipamento de aquecimento por indução. A potência decide a velocidade e a profundidade do calor no seu material. Se você usar alta potência, funciona melhor para peças grossas ou grandes. Baixa potência é boa para peças pequenas ou finas. A frequência muda como o calor se espalha no seu material. Alta frequência aquece apenas a superfície. Baixa frequência aquece mais profundamente.

Pense no que seu material é e quão grosso ele é. Metais com alta resistividade esquentam mais rápido com aquecimento por indução. Se você usar cobre ou alumínio, precisará de mais potência. Se quiser unir plásticos ou borracha, deve mudar a frequência para um melhor aquecimento. As configurações certas ajudam você a fazer ligações fortes e uniformes sempre.

Dica: Anote o tamanho e o tipo das suas peças. Isso ajudará você a escolher a melhor potência e frequência para sua máquina de aquecimento por indução.

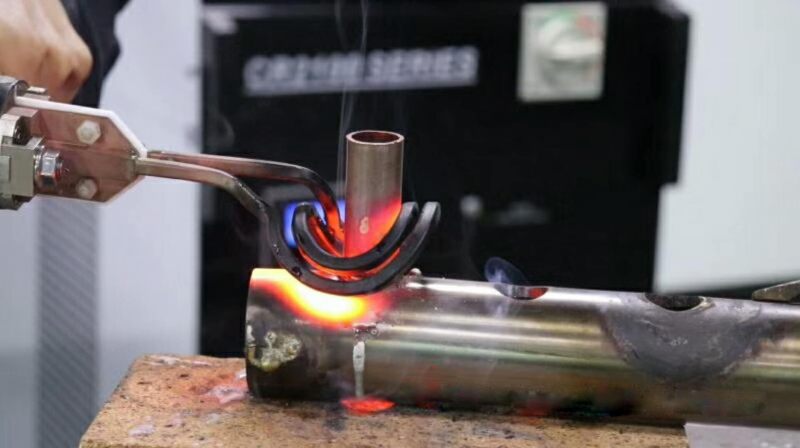

Design da Bobina e Padrão de Calor

A bobina é a parte mais importante do seu sistema de aquecimento por indução. O formato e o design da bobina decidem como o calor se espalha. Você quer uma bobina que forneça calor uniforme onde você precisa. Diferentes designs de bobina são melhores para diferentes trabalhos.

Aqui está uma tabela que mostra alguns designs comuns de bobina e o que eles fazem:

Você também pode ver como o formato da bobina muda o calor e a qualidade da ligação:

Quando você usa a bobina certa, pode controlar melhor o calor. Por exemplo, um teste mostrou que após um segundo, o quadro de ligação atingiu 343 °C. A temperatura média foi de 271 °C, e a mais baixa foi de 48.1 °C no substrato da ligação. Após dez segundos, a temperatura mais alta subiu para 513 °C. Isso significa que você pode obter aquecimento rápido e uniforme se usar a bobina certa.

Se você quiser unir peças planas, uma bobina pancake é uma boa escolha. Para peças longas ou redondas, uma bobina helicoidal de múltiplas voltas fornece uma área de aquecimento mais longa. Sempre combine a bobina com o formato e o tamanho da sua peça para os melhores resultados.

Tamanho, Portabilidade e Facilidade de Uso

Você precisa escolher equipamentos de ligação por indução que caibam no seu espaço de trabalho e sejam fáceis de usar. Alguns trabalhos precisam de máquinas que você pode mover. Outros trabalhos precisam de máquinas maiores que ficam em um lugar. Aqui está uma tabela com alguns modelos comuns e seus tamanhos:

Se você precisa de uma máquina pequena de aquecimento por indução, pode escolher modelos que pesam apenas 7.8 libras (3.5 kg). Modelos maiores pesam cerca de 44 libras (20 kg). Você pode mover essas máquinas facilmente se precisar trabalhar em lugares diferentes.

Também é importante que a máquina seja fácil de usar. Bons equipamentos de ligação por indução têmrecursos que tornam seu trabalho mais simples. Procure por esses recursos:

Você pode usar uma tela sensível ao toque para controlar a bobina de aquecimento por indução. Você pode ver a temperatura e o status do sistema imediatamente. Se houver um problema, o alarme e o guia ajudam você a corrigi-lo rapidamente. O suporte a vários idiomas ajuda todos a usar a máquina. Controle remoto e exportação de dados facilitam o gerenciamento do seu trabalho e a manutenção de registros.

Nota: Quando você escolher equipamentos de ligação por indução, sempre verifique o tamanho, o peso e os controles de usuário. Isso ajuda você a trabalhar com segurança e eficiência no seu espaço.

Considerações sobre o Sistema de Aquecimento por Indução

Propriedades do Material e Profundidade de Penetração

Quando você usa aquecimento por indução, as propriedades do material importam muito. Essas propriedades mudam a profundidade do calor na peça. O efeito pelicular mantém a maior parte do calor perto da superfície. Você precisa saber sobre resistividade e permeabilidade. Essas coisas decidem quanto calor se move dentro da sua peça. A tabela abaixo mostra como cada propriedade muda aprofundidade de penetração:

Se você usar alta frequência, o calor fica perto do topo. Baixa frequência permite que o calor vá mais fundo no material. Você pode verificar a profundidade do calor com testes como perfuração de orifícios, uso de uma fenda ou um canal anular. Esses testes ajudam você a ver se o seu equipamento de ligação por indução funciona bem para o seu trabalho.

Aumento de Calor e Eficiência

O aquecimento por indução torna as coisas muito quentes rapidamente e usa energia de forma eficiente. A energia vai direto para a peça, então você não desperdiça muita potência. A maioria dos sistemas de aquecimento por indução tem até90% de eficiência. Métodos antigos de aquecimento só atingem 40% a 60% de eficiência. Equipamentos de aquecimento por indução economizam energia gerando calor dentro da peça. Por exemplo:

Bocais de indução enviam84% da potência para a carga.

Bobinas elétricas enviam 71%.

Aquecimento a gás envia apenas 40%.

Você economiza mais energia e desperdiça menos calor com indução. Isso significa que você pode unir peças mais rápido e gastar menos dinheiro com energia.

Segurança e Manutenção

Você deve seguir as regras de segurança ao usar equipamentos de ligação por indução. Muitas fábricas precisam decertificações de segurança especiais. A tabela abaixo lista alguns padrões de segurança comuns:

Você também deve cuidar do seu equipamento de aquecimento por indução.Manutenção regular ajuda você a evitar problemas e mantém seu equipamento seguro. Aqui estão algumas tarefas importantes:

Inspecione e limpe seu equipamento com frequência.

Verifique os níveis de refrigerante e limpe os trocadores de calor.

Calibre e alinhe a máquina para um bom aquecimento.

Lubrifique as partes móveis para que não se desgastem.

Se você fizer essas coisas, seu equipamento de ligação por indução funcionará bem e permanecerá seguro.

Escolhendo um Fornecedor Confiável

Suporte e Serviço da Canroon

Você quer um fornecedor que o ajude desde o início. A Canroon oferece suporte forte paraequipamentos de ligação por indução. Eles ajudam você a configurar sua máquina e ensinam como usá-la. Se algo der errado, eles ajudam você a consertar rapidamente. Eles podem até verificar sua máquina à distância. Isso mantém seu trabalho em andamento sem parar. Se você precisar mudar sua máquina para o seu trabalho, a equipe da Canroon ajudará você. Um bom suporte significa que você não perde tempo e pode terminar seu trabalho no prazo.

Dica: Um bom serviço ajuda você a obter mais pelo seu dinheiro. Você economiza tempo e não comete erros caros.

Aqui está uma tabela que mostra o que você deve procurar em um fornecedor:

Qualidade e Longevidade do Equipamento

Você precisa de equipamentos de ligação por indução que funcionem bem por muito tempo. Boas máquinas de aquecimento por indução usam peças fortes e designs inteligentes. Você deve verificar se a máquina está aterrada e alinhada corretamente. O resfriamento é importante para que a máquina não superaqueça ou quebre. Você deve manter registros de potência, frequência e tempo de aquecimento para cada trabalho. Boas ferramentas e um bom sistema de têmpera fazem sua máquina durar mais.

Pós-Venda e Peças de Reposição

Depois de comprar equipamentos de ligação por indução, você precisa de boa ajuda e serviço. A Canroon oferece uma garantia para proteger sua máquina. Eles ajudam você a consertar ou substituir peças se algo quebrar. Você pode obter peças de reposição rapidamente para que sua máquina não pare de funcionar. Fornecedores líderes como Radyne, Ajax TOCCO e Lawatherm têm muitas peças prontas. Respostas rápidas e claras do seu fornecedor ajudam você a confiar neles e se sentir satisfeito.

Nota: Um bom suporte pós-venda ajuda você a continuar trabalhando e constrói confiança. Você obtém ajuda rápida, serviço forte e maneiras fáceis de obter peças.

Você deve escolher um fornecedor que ofereça bom suporte, máquinas fortes e peças de reposição confiáveis. Isso ajuda você a usar bem sua tecnologia de aquecimento por indução e mantém seu trabalho seguro e suave.

Você pode encontrar o equipamento de ligação por indução certo se seguir alguns passos simples. Primeiro, pense no que você precisa e veja osdetalhes técnicos. Em seguida, escolha a melhor frequência e potência para o seu trabalho. Certifique-se de que o sistema use menos energia e forneça ligações fortes. Escolha um fornecedor que saiba muito e possa ajudá-lo. Quando você combina o equipamento com o seu trabalho, obtém ligações melhores e trabalha mais rápido. A Canroon pode ajudar oferecendo conselhos e bom serviço. Você pode fazer perguntas ou experimentar uma demonstração para ver como eles podem ajudá-lo.

Perguntas Frequentes

Quais materiais você pode unir com aquecimento por indução?

Você pode unir metais, plásticos, vidro e borracha. O aquecimento por indução funciona melhor com materiais condutivos. Se o seu material não conduz, você pode precisar de um suscetor para ajudar a transferir calor.

Como você escolhe a bobina certa para sua aplicação?

Você deve combinar o formato da bobina com sua peça. Bobinas pancake funcionam bem para peças planas. Bobinas helicoidais são adequadas para peças redondas ou longas. Sempre teste diferentes bobinas para encontrar o melhor padrão de calor.

Os equipamentos de ligação por indução são seguros para uso?

Os equipamentos de ligação por indução são seguros se você seguir as regras de segurança. Procure máquinas com certificações como UL ou CE. Sempre verifique o aterramento e mantenha seu espaço de trabalho limpo.

Com que frequência você deve manter seus equipamentos de ligação por indução?

Você deve inspecionar e limpar seu equipamento regularmente. Verifique os níveis de refrigerante e alinhe a máquina antes de cada uso. Uma boa manutenção ajuda seu equipamento a durar mais.

Inscreva-se para atualizações