Você é importante para fazer soldas fortes. O pré-aquecimento ajuda a melhorar as soldas. Aquecer o metal antes de soldar reduz as mudanças de temperatura. Esta etapa evita que o metal dobre ou rache. Também remove a umidade e o hidrogênio da área de solda. Isso reduz a chance de rachaduras por hidrogênio, especialmente em aços de baixa liga. Você deve seguir regras como ASME e AWS. Estas regras dizem que você deve controlar a temperatura para cada material e espessura. Escolher o equipamento de pré-aquecimento para solda certo ajuda você a seguir estas regras. Marcas como Canroon fornecem bons equipamentos para o seu trabalho.

Principais Conclusões

Pré-aquecer o metal antes de soldar melhora as soldas. Reduz a chance de rachaduras e problemas. Permite que o metal esfrie mais lentamente. Isso torna a solda mais forte.

Conhecer o tipo e a espessura do metal é importante. Ajuda você a escolher oequipamento de pré-aquecimento certo. Metais diferentes precisam de temperaturas de pré-aquecimento diferentes.

Sempre siga os códigos e padrões de soldagem como ASME e AWS. Estas regras ajudam a mantê-lo seguro. Também garantem que seu projeto siga a lei.

Considere fatores como temperatura e umidade ao escolher o equipamento. Você pode precisar ajustar coisas para clima frio ou úmido.

Compre equipamentos que funcionem bem e tenham bom suporte. Treinamento e ajuda de especialistas podem melhorar sua equipe. Isso pode ajudar seu projeto a ter sucesso.

Por Que o Pré-Aquecimento é Essencial

Impacto na Qualidade da Solda

Você quer que suas soldas permaneçam fortes por muito tempo. O pré-aquecimento é muito importante para isso. Quando você usaequipamento de pré-aquecimento para solda, você aquece o metal antes de soldar. Esta etapa muda como o metal se comporta durante e após a soldagem.

Dica: O pré-aquecimento ajuda o metal a esfriar lentamente. O resfriamento lento torna rachaduras e fragilidade menos prováveis.

O pré-aquecimento melhora a qualidade da solda de várias maneiras:

Elereduz a chance de rachaduras e pequenos furos ao permitir que o hidrogênio saia do metal.

Torna o metal mais macio e fácil de dobrar, para que a solda não quebre facilmente.

Reduz o estresse dentro do metal, para que a solda não torça ou dobre.

Ajuda a solda a se unir melhor com o metal base, tornando a junta mais forte.

Você pode ver a diferença em soldas com e sem pré-aquecimento na tabela abaixo:

Prevenindo Rachaduras e Defeitos

O pré-aquecimento ajuda você a evitar muitos problemas de soldagem. Rachaduras a frio, também chamadas de rachaduras induzidas por hidrogênio, acontecem quando você ignora o pré-aquecimento. Estas rachaduras podem aparecer horas ou dias após a soldagem. Elas geralmente se formam na zona afetada pelo calor ou no metal de solda, especialmente em aços carbono ou de liga.

O pré-aquecimento previne defeitos das seguintes maneiras:

Remove umidade e hidrogênio, que causam rachaduras a frio.

Reduz a diferença de temperatura entre a solda e o metal base, para que o metal não rache devido ao estresse.

Ajuda você a seguir códigos e padrões de soldagem, que frequentemente exigem pré-aquecimento para alguns materiais e espessuras.

Quando você usa oequipamento de pré-aquecimento para solda certo, suas soldas são mais seguras e confiáveis. Você também economiza tempo e dinheiro porque não precisa de reparos ou retrabalhos.

Avaliando as Necessidades do Projeto

Tipo de Material e Espessura

Você deve saber qual metal você tem antes de escolher o equipamento. Cada metal reage de sua própria maneira quando aquecido. Aço, aço inoxidável e ferro fundido precisam de temperaturas de pré-aquecimento diferentes. Metal grosso retém calor por mais tempo e esfria lentamente. Metal fino esfria rápido e pode não precisar de muito pré-aquecimento.

Ao planejar seu projeto, observe estas coisas:

Regras do código para seu metal e solda

Quão grosso é o metal

O que está no metal base, como carbono ou liga

Quanto o metal pode se mover durante a soldagem

A temperatura na sua área de trabalho

Quanto hidrogênio está no metal de enchimento

Se você teve problemas de rachaduras antes

Por exemplo, aços de alta resistência e ferro fundido precisam de mais calor. Se você pular o pré-aquecimento, estes metais podem rachar ou quebrar. Peças grandes e complexas precisam de calor uniforme em todos os lugares. Você pode precisar deequipamento de pré-aquecimento para solda avançado para manter toda a peça quente.

Códigos e Padrões de Soldagem

Você deve seguir códigos e padrões de soldagem para seu projeto. Estas regras ajudam você a fazer soldas seguras e fortes. Códigos como ASME e AWS informam a temperatura correta de pré-aquecimento para cada metal e espessura. Eles também dizem como verificar e controlar o calor.

Se você não seguir estas regras, suas soldas podem falhar. Você também pode ter riscos de segurança ou problemas legais. Sempre verifique o código para seu projeto antes de escolher o equipamento de pré-aquecimento para solda. Este passo ajuda você a evitar erros e mantém seu trabalho seguro.

Dica: Anote as regras do código para seu projeto antes de começar. Isso ajuda você a escolher o equipamento e configurações certos.

Fatores do Ambiente de Trabalho

Sua área de trabalho muda como você pré-aquece o metal. Clima frio significa que você precisa de temperaturas de pré-aquecimento mais altas. Ar úmido adiciona umidade, que pode causar rachaduras por hidrogênio. Você deve ajustar seu equipamento de pré-aquecimento para solda para estas condições.

Aqui está uma tabela para mostrar como o ambiente afeta sua escolha:

O tamanho e a forma do projeto também importam. Projetos grandes precisam de maneiras especiais de espalhar o calor uniformemente. Formas estranhas dificultam manter toda a peça quente. Você pode precisar de ferramentas especiais para evitar rachaduras e dobras.

Quando você pensa em todas estas coisas, pode escolher o melhor equipamento de pré-aquecimento para solda para seu trabalho. Isso ajuda você a fazer soldas fortes e seguras sempre.

Tipos de Equipamento de Pré-Aquecimento para Solda

Escolher o equipamento de pré-aquecimento para solda certo ajuda você a trabalhar melhor. Pode tornar seu trabalho mais rápido e seguro. Existem diferentes tipos para diferentes trabalhos e materiais. Vamos aprender sobre os principais tipos e como eles são diferentes.

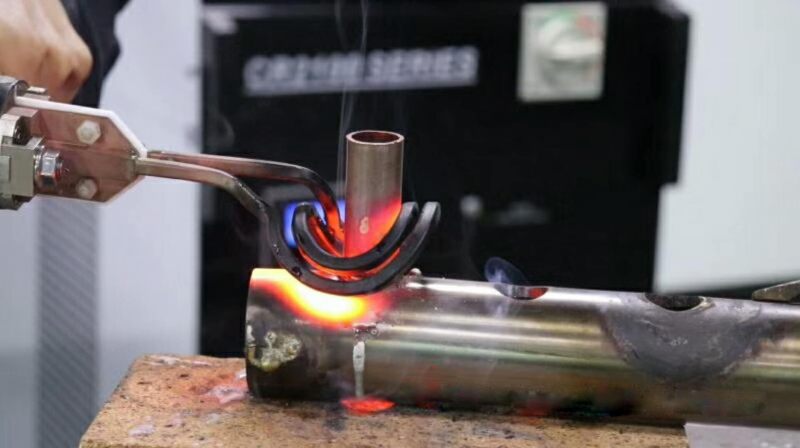

Sistemas de Aquecimento por Indução

Sistemas de aquecimento por indução usam campos eletromagnéticos para aquecer o metal. Você coloca uma bobina perto ou ao redor da peça de metal. O sistema envia eletricidade através da bobina. Isso cria um campo magnético que aquece o metal rapidamente e uniformemente.

Por que escolher aquecimento por indução?

Você obtém alta eficiência, geralmente entre 70% e 90%.

Você pode controlar a temperatura muito bem. Aquece apenas a área que deseja.

Você economiza energia. O aquecimento por indução usa menos energia do que métodos antigos.

Você termina trabalhos mais rápido. O tempo de pré-aquecimento pode cair de20-25 minutos para 5-10 minutos.

Você obtém aquecimento uniforme, o que ajuda a evitar rachaduras e defeitos.

Melhor para:

Tratamento térmico, soldagem, brasagem e derretimento de metais. Você pode usá-lo em muitas formas e tamanhos.

Nota: As soluções de aquecimento por indução da Canroon são confiáveis. Elas têm certificações ISO 9001 e CE. A maioria dos pedidos chega no prazo. Você pode obter máquinas personalizadas ou ajuda com protótipos rapidamente.

Ferramentas de Aquecimento por Resistência

Ferramentas de aquecimento por resistência usam fios ou almofadas elétricas para aquecer o metal. Você enrola os fios ou almofadas ao redor da peça. A eletricidade aquece os fios. O calor passa para o metal.

Por que escolher aquecimento por resistência?

Você obtém bom controle sobre a temperatura.

Você pode usá-lo para muitas formas. Funciona melhor para peças simples.

Você pode usá-lo para fornos e aquecimento de coisas não metálicas.

Coisas a considerar:

A eficiência é menor do que a indução, geralmente 45% a 75%.

Leva mais tempo para aquecer peças grossas ou grandes.

Você pode usar mais energia do que com aquecimento por indução.

Melhor para:

Aquecimento ambiente, fornos e trabalhos que precisam de calor constante e suave.

Métodos de Forno e Estufa

Fornos e estufas aquecem peças com ar quente por todos os lados. Você coloca toda a peça dentro da câmara. O calor se espalha para todas as superfícies.

Por que escolher fornos ou estufas?

Você pode aquecer peças grandes ou complexas de uma vez.

Você obtém aquecimento uniforme, o que ajuda com soldas grandes.

Coisas a considerar:

Estes sistemas não são portáteis. Você deve mover a peça para o forno.

Eles usam muita energia e levam tempo para aquecer e esfriar.

Não são bons para trabalhos rápidos ou em campo.

Melhor para:

Peças grandes, trabalhos em lote ou quando você precisa aquecer muitas peças de uma vez.

Opções de Gás, Infravermelho e Chama Aberta

Métodos de gás, infravermelho e chama aberta usam queimadores ou lâmpadas para aquecer o metal. Você pode usar gases como acetileno, GLP, propileno ou gás natural. A chama ou lâmpada aquece a superfície do metal.

Por que escolher estes métodos?

Você pode usá-los ao ar livre ou em peças grandes e difíceis de mover.

Novos designs de tochas e o uso de ar como oxidante tornam o aquecimento por chama mais seguro.

Aquecedores infravermelhos fornecem calor mais uniforme e reduzem a oxidação em comparação com chamas abertas.

Coisas a considerar:

O aquecimento por chama aberta pode causar calor desigual e mais oxidação. Muitos códigos não permitem chama aberta para alguns metais.

Aquecedores a gás podem ser perigosos devido ao fogo e exposição ao gás.

Aquecedores infravermelhos são mais seguros, mas ainda precisam de cuidado.

Melhor para:

Trabalhos rápidos, reparos ou quando você não pode usar sistemas elétricos. Estes métodos são comuns na fabricação de trocadores de calor, especialmente com aços cromo-molibdênio.

Gases e oxidantes comuns:

Acetileno, GLP, propileno, gás natural

Oxigênio, ar comprimido ou ar atmosférico

Dica: Sempre verifique as regras de segurança do seu projeto antes de usar métodos a gás ou chama aberta.

Comparando os Principais Tipos

Aqui está uma rápida comparação dos principais tipos:

Ao escolher equipamento de pré-aquecimento para solda, pense no tamanho, material e localização do seu projeto. O aquecimento por indução oferece velocidade, economia de energia e qualidade. Métodos de resistência e forno funcionam bem para trabalhos constantes e controlados. Opções de gás e chama ajudam quando você precisa trabalhar ao ar livre ou em peças grandes.

Principais Recursos para Comparar

Ao escolher equipamento de pré-aquecimento para solda, observe algumas coisas importantes. Estas coisas ajudam você a obter bons resultados para seu projeto.

Controle e Precisão de Temperatura

Você precisa manter a temperatura correta ao soldar. Bom controle de temperatura torna as soldas fortes e seguras. Se você usar muito calor, o metal pode dobrar ou mudar de cor. Se usar pouco calor, a solda pode não segurar. Manter o calor constante evita soldas frias e superaquecimento. Metal limpo e calor uniforme também melhoram as soldas.

Se você não aquecer superfícies de tubos uniformemente, obtém pontos fracos, lacunas e juntas frágeis. Muito calor pode danificar o tubo e mudar sua cor ou forma. Pouco calor significa que o tubo não amolece o suficiente, então pode vazar.

Mobilidade e Flexibilidade

Às vezes você precisa mover suas ferramentas para diferentes lugares. Ferramentas leves e fáceis de carregar ajudam você a trabalhar mais rápido. Você pode consertar coisas rapidamente e voltar ao trabalho. Ferramentas portáteis também ajudam você a seguir regras para trabalhos em campo.

Controles e Monitoramento Digital

Muitas novas ferramentas de pré-aquecimento para solda têm controles digitais. Estes permitem que você veja a temperatura enquanto trabalha. Você pode encontrar problemas cedo e corrigi-los rápido. Ferramentas digitais ajudam você a seguir regras de soldagem mantendo o calor na faixa certa.

Observar a temperatura em tempo real ajuda você a detectar problemas.

Rastreamento digital permite que você veja pequenos problemas e melhore seu trabalho.

Imagem térmicaverifica se você tem o calor certo para cada solda.

Controles automáticos mantêm o calor constante e evitam erros.

Comprimento do Cabo e Necessidades de Energia

Verifique o comprimento do cabo e a energia antes de começar. Cabos longos ajudam você a alcançar peças grandes ou difíceis de mover. Certifique-se de que sua energia corresponda à ferramenta. Se usar energia errada, a ferramenta pode não funcionar ou quebrar. Sempre planeje cabo suficiente e a energia certa para terminar seu trabalho com segurança.

Escolher os recursos certos ajuda você a obter o melhor uso do seu equipamento de pré-aquecimento para solda.

Segurança, Conformidade e Suporte

Atendendo aos Padrões de Segurança

Você deve sempre pensar em segurança ao escolherequipamento de pré-aquecimento para solda. Regras de segurança protegem você e sua equipe de queimaduras, incêndios e choques elétricos. Códigos como ASME e AWS estabelecem regras claras para como aquecer o metal antes de soldar. Estes códigos ajudam você a fazer soldas fortes e evitar acidentes. Você deve verificar se seu equipamento tem recursos de segurança como desligamento automático, alarmes de temperatura e instruções claras. Usar equipamento que atende a estes padrões mantém seu trabalho seguro e ajuda você a passar em inspeções.

Dica: Sempre leia o manual de segurança antes de começar. Este passo ajuda você a evitar erros e mantém todos seguros.

Suporte e Treinamento do Fornecedor

Bom suporte do fornecedor do equipamento torna seu trabalho mais fácil. Você quer uma empresa que ajude você a aprender e resolver problemas. Canroon e outras marcas confiáveis oferecem treinamento e ajuda técnica. Este suporte oferece muitos benefícios:

Treinamento ajuda você e sua equipe a usar o equipamento corretamente.

Você aprende como ficar seguro durante a soldagem.

Você obtém melhores resultados e termina trabalhos mais rápido.

Sua equipe se sente mais confiante e permanece mais tempo em sua empresa.

Ao escolher um fornecedor, pergunte sobre seus programas de treinamento e quão rápido eles respondem perguntas. Bom suporte significa que você pode resolver problemas rapidamente e manter seu projeto no prazo.

Custo e Valor a Longo Prazo

Você deve olhar mais do que apenas o preço ao comprar equipamento de pré-aquecimento para solda. Pense em como o equipamento ajudará você ao longo do tempo. O tipo de metal, sua espessura, o processo de soldagem e o ambiente de trabalho mudam o valor que você obtém. Aqui está uma tabela para ajudá-lo a comparar:

Você economiza dinheiro a longo prazo ao escolher equipamento que atenda suas necessidades e dure muito tempo. Bom suporte e treinamento também agregam valor ajudando você a evitar erros e reparos.

Você pode escolher o equipamento de pré-aquecimento para solda certo usando um plano simples. Primeiro, verifique que tipo de metal você tem e quão grosso ele é. Limpe a superfície do metal antes de começar. Escolha o método de aquecimento que funciona melhor para seu trabalho. Configure ferramentas para monitorar a temperatura. Aqueça o metal lentamente e certifique-se de que está uniforme. Mantenha a temperatura correta até terminar a soldagem. Anote tudo o que você faz para ficar seguro.

Lista de Verificação para Sucesso:

Encontre a temperatura correta de pré-aquecimento.

Limpe bem sua área de trabalho.

Escolha o melhor método de aquecimento.

Monitore a temperatura o tempo todo.

Aqueça o metal lentamente e uniformemente.

Mantenha o pré-aquecimento durante a soldagem.

Anote cada passo que você der.

Para melhores resultados, peça ajuda a especialistas ou marcas confiáveis como Canroon. Eles podem ajudá-lo a planejar, treinar e fornecer suporte.

Quando seu equipamento corresponde ao seu projeto, você obtém soldas fortes e seguras sempre.

Perguntas Frequentes

Qual é a principal razão para pré-aquecer antes de soldar?

Você pré-aquece o metal para evitar rachaduras e defeitos. O pré-aquecimento permite que o metal esfrie lentamente. Isso torna suas soldas mais fortes e seguras.

Como você escolhe a temperatura correta de pré-aquecimento?

Verifique o código de soldagem do seu projeto. Olhe o tipo e a espessura do seu metal. Use um gráfico de temperatura ou pergunte a um especialista se não tiver certeza.

Você pode usar o mesmo equipamento para todos os metais?

Não. Metais diferentes precisam de métodos de aquecimento diferentes. Por exemplo, aço e alumínio precisam de ferramentas diferentes. Sempre combine seu equipamento com seu metal.

O aquecimento por indução é seguro para trabalhos em campo?

Sim. O aquecimento por indução é seguro se você seguir as instruções. Ele fornece calor uniforme e tem recursos de segurança. Sempre use equipamento de proteção e verifique suas ferramentas antes de usar.

Inscreva-se para atualizações